- in Acoustics by Bobby Owsinski

- |

- 1 comments

New Sound Diffusor Is Way Thinner Than The Current Ones

When building a studio without the help of a professional, most people are concerned with getting even absorption across the frequency spectrum. They don’t think about diffusion until later in the construction process, and then are shocked to discover that effective diffusors can take up more space than they were anticipating. Diffusors are important to a good sounding room in that they can scatter sound waves in many different directions, which can eliminate those echoes and rings that we hate so much.

When building a studio without the help of a professional, most people are concerned with getting even absorption across the frequency spectrum. They don’t think about diffusion until later in the construction process, and then are shocked to discover that effective diffusors can take up more space than they were anticipating. Diffusors are important to a good sounding room in that they can scatter sound waves in many different directions, which can eliminate those echoes and rings that we hate so much.

Most diffusers in use today are Schroeder diffusers, which are comprised of a number of wells of different at carefully chosen depths. This was developed by Manfred Schroeder, a professor of speech and acoustics at the University of Goettingen, Germany in the 1970s. Schroeder conducted a study of the great concert halls of Europe and found that listeners liked the sound of long, narrow venues better than ones were wide, mostly because they prefer to hear the difference between frequencies that arrive at different times at each of their ears. That lead to the development of his diffusor, which has been a staple in recording studios and rooms needing acoustic control ever since.

The reason why diffusors are so important to a great sounding room is that they feel like they give the room “air” and make the walls seemingly disappear. That’s because of the varying depths of the wells of the diffusor has the ability to scatter a broad range of frequencies. The problem is, the lower the frequencies that you want to scatter, the larger the diffusor has to become. Most of them are made with wood, so a diffusor trying to scatter frequencies below 500Hz becomes heavy and bulky.

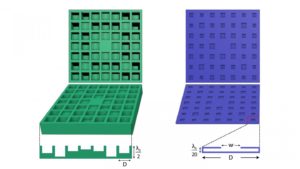

Yun Jing, an assistant professor of mechanical and aerospace engineering at North Carolina State University, found a way to make a typical Shroeder diffusor 10 times thinner than what we use today. His ultra-thin diffuser also consists of evenly spaced squares, but the squares are different sizes and act as an aperture that opens into a thin, underlying chamber. These chambers all have identical dimensions, but since the size of the apertures are each different, they work the same as the much thicker Schroeder diffusers. A workable prototype has already been made using a 3D printer.

This is great news for studio owners and designers everywhere, as pretty soon you can have the benefits of better diffusion but in a lot less space.